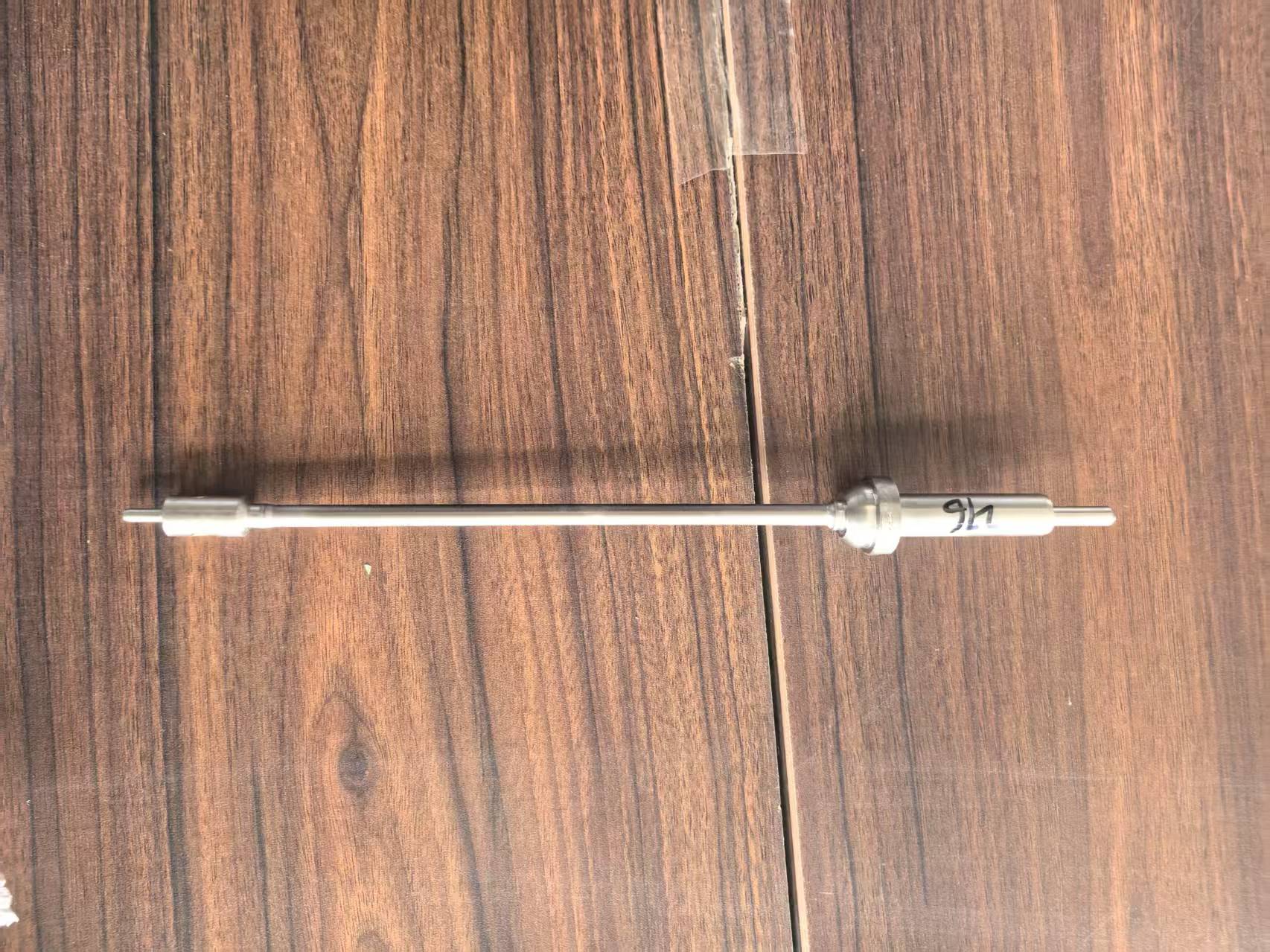

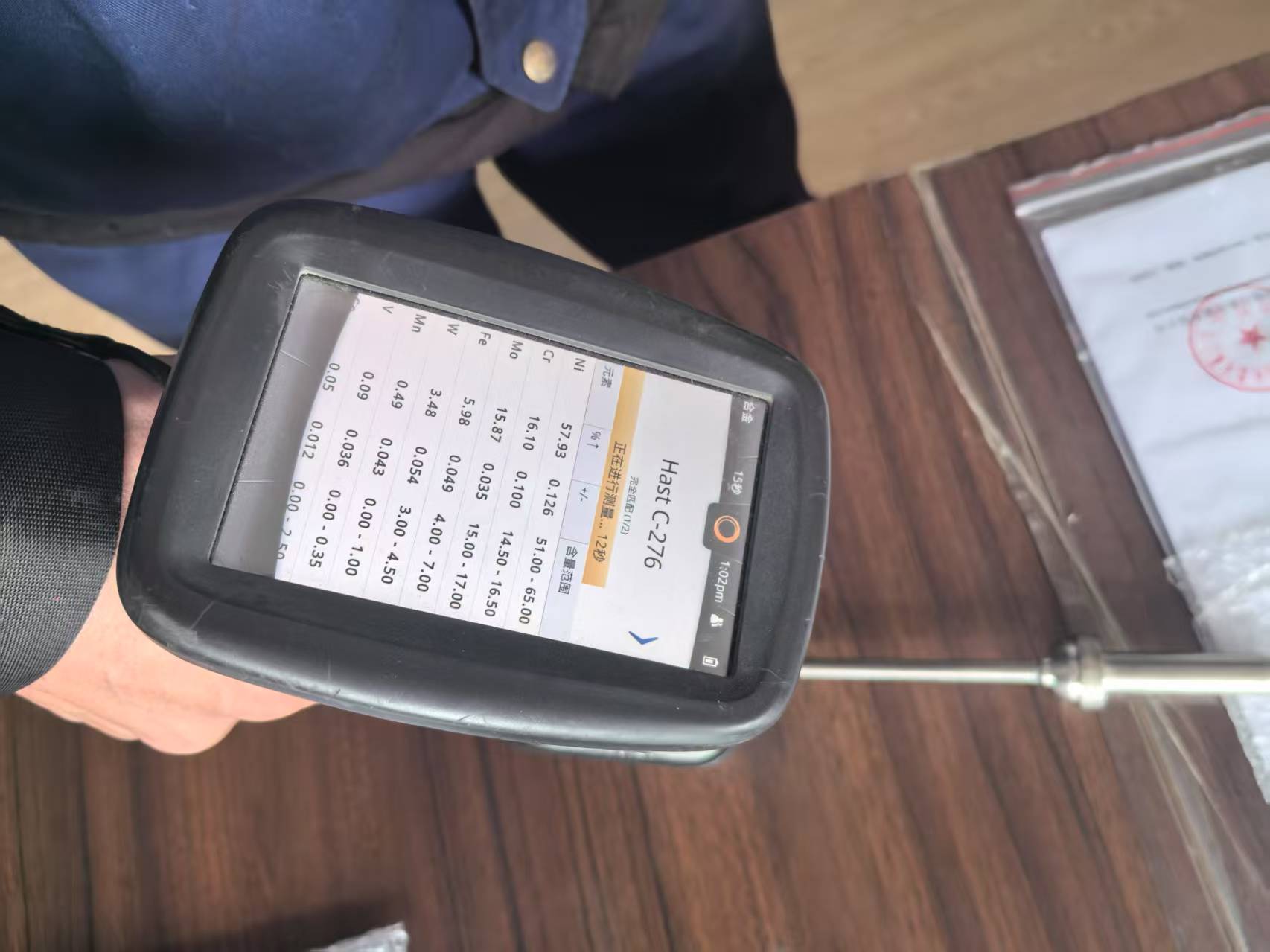

C 276 material torque tube for 244LD displacer level transmitter

The change in the liquid level of the measured medium causes a change in the buoyancy of the inner cylinder, which is transmitted to the torque tube assembly to rotate the torque tube at an angle simultaneously. A sensing system coupled to the torque tube mandrel generates a voltage signal. The level controller electronic component measures the fluid (boundary) signal to provide 4 ~ 20 mA current output. The ambient temperature measured by the microcontroller can compensate for the changes in the liquid density due to the process temperature changes. LCD can display information about analog output, process variables and percentage range of liquid (boundary) bits.

2.3 Packaging

Please send the packaging waste to a specialized recycling facility.

2.4 During hoisting and transportation

Please select qualified lifting equipment and lifting belt, and pay attention to safety.

2.5 Warehousing

Storage temperature is-20℃ ~40℃; storage humidity is 40%.

3 Technical features

3.1 Main performance

3.1.1 It has passed the national explosion-proof certification

Certification mark: safety type Ex ia ⅡCT4 ~ T 6 Ga

Burtal type Ex db ⅡCT4 to T 6 Gb

3.1.2 Product implementation standards

GB / T13969 float type liquid level instrument.

3.2 Main parameters

3.2.1 Power supply voltage: 12~30V DC.

3.2.2 Output signal: 4 ~ 20 m ADC.

4 Schemram of external dimensions

If a special size is required in order, the actual size shall prevail.

5 Open the box and check

5.1 Notes for unpacking and inspection

5.1.1 Whether the reference product nameplate is consistent with the supply list information.

5.1.2 Check the quantity of each part and the correct material according to the packing list.

5.2 Check the content

5.2.1 Check the instrument appearance for defects, damage and other abnormal conditions.

5.2.2 If the UTZ intelligent buoy transmitter and other parts use separate packaging.

6 Installation

6.1 Install the tools

6.1.1 Wrench, flange spacers and flange bolts for process connections

6.1.2 Level

6.2 Installation technical requirements

6.2.1 When installing the measuring room, the flange axis of the outer cylinder side must be perpendicular to the horizontal plane (calibrated with the horizontal meter). If the UTZ intelligent buoy transmitter and other parts are packed separately, it shall be installed according to the positions shown in the product structure diagram; if the whole part has been installed, operate according to 6.3.5.

6.2.2 Installation of the transmitter and the inner tube: hold the hanging plate on the inner tube by hand and hang it on the top of the transmitter lever.

6.3 Installation and operation process

6.3.1 Remove the bolt nut connecting the flange cover and the outer cylinder, remove the gasket, and place one gasket on the flange sealing surface at the upper end of the outer cylinder, as shown in the figure.

6.3.2 Connect the inner cylinder and the transmitter according to 6.2.2, and put it into the outer cylinder to ensure that the ring flange of the transmitter is in good contact with the gasket.

6.3.3 Place the other gasket on the sealing surface of the flange cover, and install the flange cover on the transmitter ring flange. Ensure that the transmitter ring flange has good contact with the gasket, and align the flange bolt holes, as shown in the figure.

6.3.4 Install the bolts and nuts connecting the flange cover with the outer cylinder, and tighten the nuts alternately, as shown in the figure.

6.3.5 Install the outer cylinder side flange on the device to ensure that the flange has a good contact with the gasket, as shown in the figure

7 Debug

7.1 Commissioning preparation

7.1.1 Commissioning tools

1) Power supply

2) The 250 Ω ~500 Ω resistance used for the HART communication protocol

7.2 Electrical wiring

7.2.1 Unscrew the cover of the power terminal box and connect each current signal cable. + Connect to the positive terminal of the power supply, - Connect to the negative terminal of the power supply

7.2.2 After completing the wiring, check whether the polarity of the wiring is correct, the meter housing must be well grounded, and then connect the 24VDC standard power supply.

7.3 Commissioning of the operation process

7.3.1 Notes before commissioning

1) The instrument shall not be subjected to strong vibration and impact, especially for the lever hung with the inner cylinder, and shall not be vigorously pulled down to avoid damage to the torque pipe.

2) The instrument shall not participate in the impact process test such as gas sweeping of the device before putting into operation.

7.3.2 During commissioning, if the water is the medium (non-measured medium), the following two situations will occur: ρ medium <ρ water and ρ medium> ρ water. However, no matter how the medium density is, the corresponding water injection height and the corresponding output current value can be calculated by the formula: h water injection height = ρ medium · H full range height / ρ water.

The instrument has been calibrated before delivery.

7.3.3 Adjust the field LCD display value

Instrument field adjustment

The field configuration can realize the setting of configuration data such as unit, range, damping, display variable, measurement type, density, buoy height and working G value, calibration upper and lower limits and fixed-point fine-tuning.

You can also view the above configuration data, design density, and calibrate G values.

Key mode description

This product supports two operation modes: "double keys" and "three keys".

In the "double button" operation mode: Z key is used to enter the prompt data setting interface and shift; S key is used to enter the data setting interface and increase the number and data saving.

In the "three keys" operation mode: Z key is used to enter the prompt data setting interface and shift; S key is used to enter the data setting interface and increase the number and data saving; and M key is used for data saving.

Data setting method

When the "88" character in the lower left corner shows 1~24, it indicates that the transmitter is in the field configuration mode, when you can enter the password and modify the parameters by pressing the key.

During data setting, "S" is used to adjust numbers and decimal points, "Z" is used for shifting, and "M" is used for saving.

The setup process is as follows:

Press the S key to enter the data setting interface, and the symbol bit starts to flash to indicate the modified symbol bit.

If you press the S key again, you can switch the positive and negative data (the positive sign is indicated by the upper arrow).

Press Z key, the first digit starts to blink, which means modifiable. Long press or press S key several times, and set the number to cycle between 0 and 9.

Press the Z key again, you can set the second digit to the fifth digit in turn, the setting method is exactly the same as the first one.

After setting the fifth number, press the Z key to start setting the decimal point. Four decimal points start flashing at the same time, indicating that the decimal point can be set, press S, and the position of the decimal point is switched around.

After the decimal point setting, press Z and the lower left arrow flashes to indicate that the settings can be saved.