Foxboro 244LD buoyancy displacer level transmitter

- schneider

- France

- 30 days

- 500 sets/month

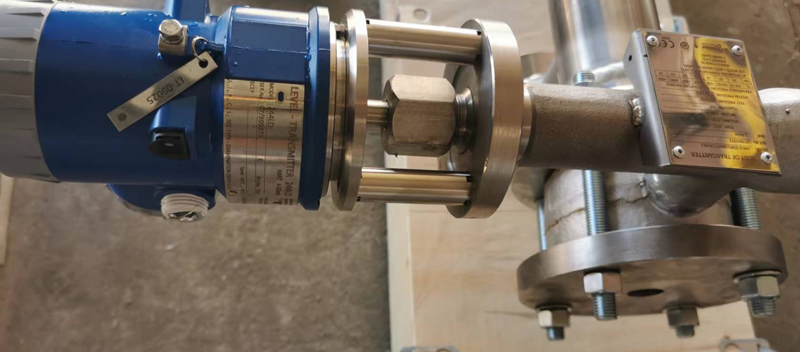

The intelligent FOXBORO Level Star 244LD Level transmitter is designed to perform continuous measurements for liquid level, interface or density of liquids in the process of all industrial applications. Original import from Schneider France plant

244LD LevelStar Intelligent Buoyancy Transmitter/Foxboro transmitter /244LD transmitter/for Level, Interface

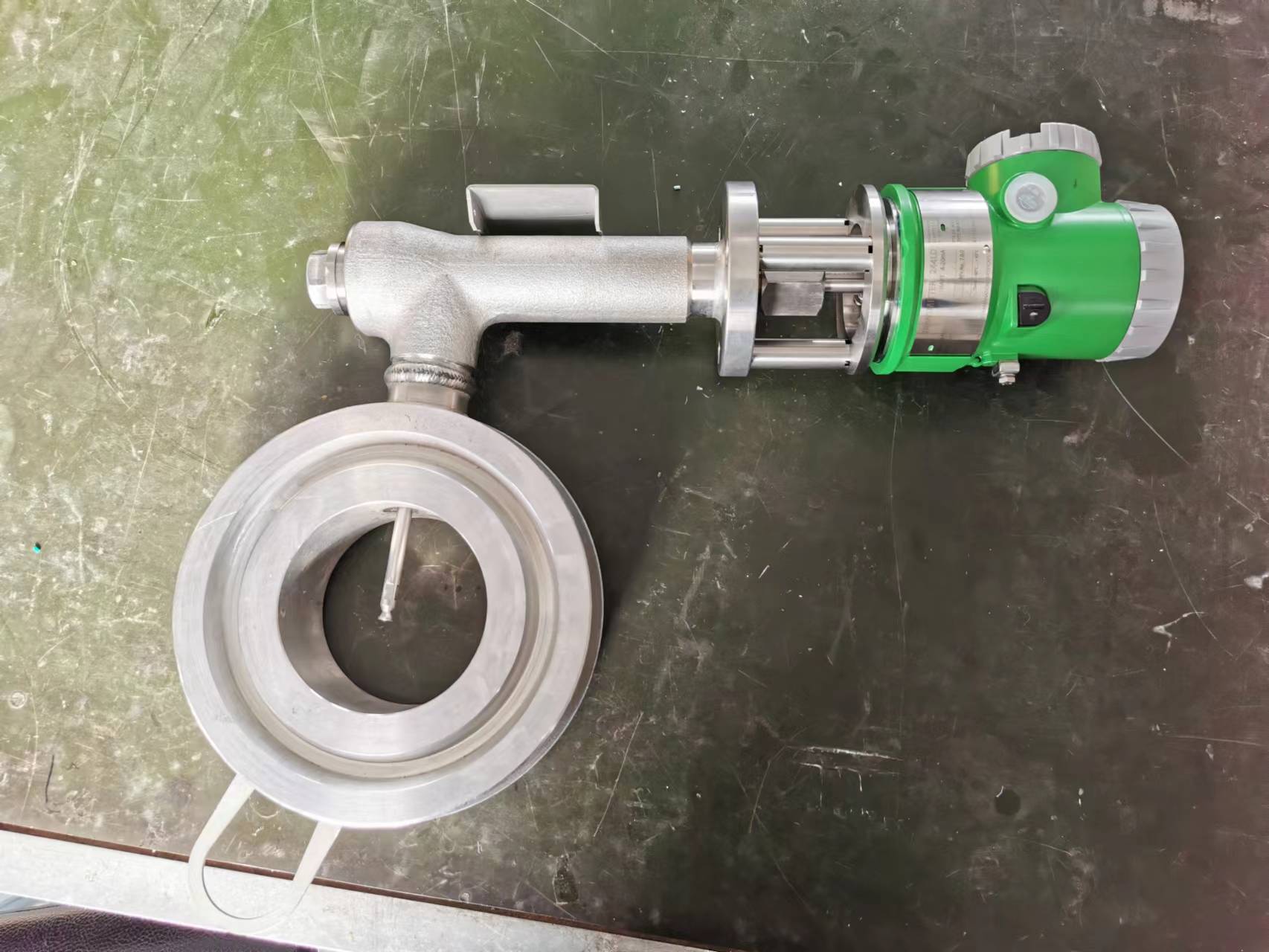

foxboro 244LD displacer level transmitter

Foxboro transmitter

244LD transmitter

FOXBORO 244LD

FOXBORO 244LD transmitter

original from France with CO

316LSS wafer body, flange, torque tube

for 900# with 16Mpa

RF face, LM, B1/B2, RTJ, optional

buoyancu level transmitter/Foxboro transmitter/FOXBORO 244LD transmitter

244LD transmitter

flange size DN80 or DN100

material can be carbon steel, stainless, mobel, inconel, Hastalloy etc

244LD foxboro displacer level transmitter/244LD transmitter

244LD foxboro displacer level transmitter

The intelligent transmitter 244LD LevelStar level transmitter/Foxboro transmitter/244LD transmitter/FOXBORO 244LD transmitter is designed to perform continuous measurements for liquid level, interface or density of liquids in the process of all industrial applications. The measurement is based on the proven Archimedes buoyancy principle and thus extremely robust and durable. Measuring values can be transferred analog and digital. Digital communication facilitates complete operation and configuration via PC or control system. Despite extreme temperatures, high process pressure, and corrosive liquids, the 244LD measures with consistent reliability and high precision. It is approved for installations in contact with explosive atmospheres. The 244LD transmitter combines our abundant experience with most advanced digital technology.

FEATURES of Foxboro 244LD buoyancy displacer level transmitter/244LD transmitter/FOXBORO 244LD

• HART 7 Communication, 4 to 20 mA, or Foundation Fieldbus

• Configuration via FDT-DTM

• Multilingual full text graphic LCD

• IR communication as a standard

• Easy adaptation to the measuring point without calibration at the workshop

• Linear or customized characteristic

• 32 points linearization for volumetric measurement

• Approved for SIL 2 applications (at HART)

FOXBORO 244LD transmitter

• Back documentation of measuring point

• Continuous self diagnostics, Status, and diagnostic messages

• Configurable safety value

• Local display in %, mA, or physical units

• Process temperature from – 196 °C to +500 °C

• Materials for use with aggressive media

• Micro sinter metal sensor technology

FOXBORO 244LD transmitter |

FOXBORO 244LD |

Packing and delivery for Foxboro 244LD buoyancy displacer level transmitter/Foxboro transmitter

Adopts polywood case, film wrap on the 244LD Foxboro transmitter for protection

About us

Dandong Naineng Instrument&Electric Co.,Ltd located in Dandong of China, professional in level, flow transmitters include imported brand foxboro 244LD displacer level transmiter,

Emerson fisher DLC3100 249 displacer level transmitter, our own brand Dedan displacer level transmitters, off set glass plate gauge, magnetic level indicator, 80G non contact radar level transmitters, guilded wave radar level transmitters, intelligent big ball float level transmitters,magnetostrictive level transmitters, displacer level switch, orifice flow meters, venturi, magnetic flow meters, turbine flow meters, vertex flow meters, rotary vane displacement rotary vane flow meters, metal tube variable flow meters, etc