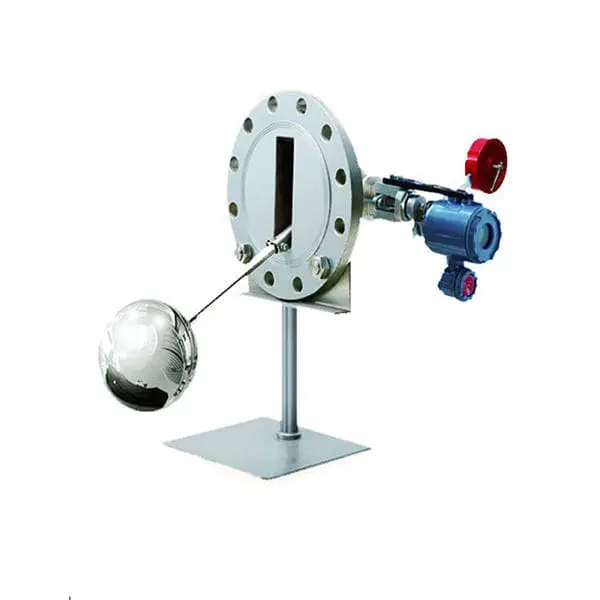

Magnetostrictive Level Transmitter

- Dedan

- China

- 30 days

- 500 sets/month

Magnetostrictive level transmitters is designed according to the magnetostrictive principle, which is a highly accurate, respond fast, good reliability, long life, smart structure level measuring instrument.

MLT series Magnetostrictive Level Transmitter

Summary

MLT magnetostrictive level transmitters is designed according to the magnetostrictive principle, which is a highly accurate, respond fast, good reliability, long life, smart structure level measuring instrument.

Magnetostrictive level transmitter adopts two-wire system 4-20mA with HART for level measuring, which is widely used in the applications of petroleum, chemical, food , metallurgy and so on.

Main technical parameters

Power supply: 9 ~ 28V DC

Output signal: 4 to 20mA+HART

Range: 40mm ~4000mm

Probe diameter: Φ12mm

Operating pressure: ≤5.0MPa

Medium temperature: -40℃ ~ +160℃

Ambient temperature: -40℃ ~ +80℃

Accuracy: ±1mm

Resolution: ≤0.1mm

Temperature influence: ≤±0.01%/℃

Min. density difference: 0.5g/cm³

Wetted material: 316L, Hastelloy C-276 (or on request)

Process connection: G1/2″, standard flange (or on request) or others

Power supply inlet: M20×1.5 (female thread)

Explosion-proof: Intrinsically safe Ex ia IIBT5/T6 Ga;

Explosion isolation Ex d IICT3/T6 Gb

Protection class: IP67

model selection of magnetostrictive level transmitter

Model | Code | Code meaning | |||||

MLT- | MLT magnetostrictive level transmitters | ||||||

probe material | |||||||

1 | 316L | ||||||

2 | Hastelloy C-276 | ||||||

3 | others | ||||||

signal output | |||||||

s | measuring level | ||||||

i | measuring interface | ||||||

d | measuring level and interface | ||||||

t | measuring level, interface and temperature | ||||||

process connection | |||||||

1 | top mounted thread G1/2 | ||||||

2 | top mounted flange | ||||||

3 | side-side mounted | ||||||

4 | side-side mounted with float | ||||||

5 | top mounted with float | ||||||

6 | others | ||||||

explosion-proof | |||||||

i | Intrinsically safe | ||||||

d | Explosion isolation | ||||||

float material | |||||||

0 | no float | ||||||

1 | φ52, 316L, 20bar≥0.6g/㎝² | ||||||

2 | Φ43, 316L, 50bar≥0.95g/㎝² | ||||||

3 | CylinderΦ43, 316L, 50bar≥0.95g/㎝² | ||||||

4 | Φ43, 316L 20bar≥0.85g/㎝² | ||||||

5 | Φ52, 316L, 40bar≥0.7g/㎝² | ||||||

6 | Φ50, Ti, 20bar≥0.5g/㎝² | ||||||

7 | CylinderΦ46, C276, 10bar≥0.7g/㎝² | ||||||

8 | others | ||||||

probe length | probe length=range+300mm | ||||||

Order requirements of magnetostrictive level transmitter

a. If process connection is flange connection, you must provide the following parameters:

Nominal diameter\Pressure class\Flange standard (Indicated in the selection);

b. Confirm the bottom fixed mode: none, heavy punch or hook;

c. According to the corrosivity of the medium to be measured to determine the probe rod material;

d. If you need to order the float, also need to provide the density range of the measured upper medium and lower medium, so that we can help you to select the float model